Make the switch to Solid Edge

Thinking about making the switch to Solid Edge? Discover how you can get more out of your CAD and product development software investment to maximize productivity while decreasing costs. Get in touch with our sales team today to explore your options!

Media coverage

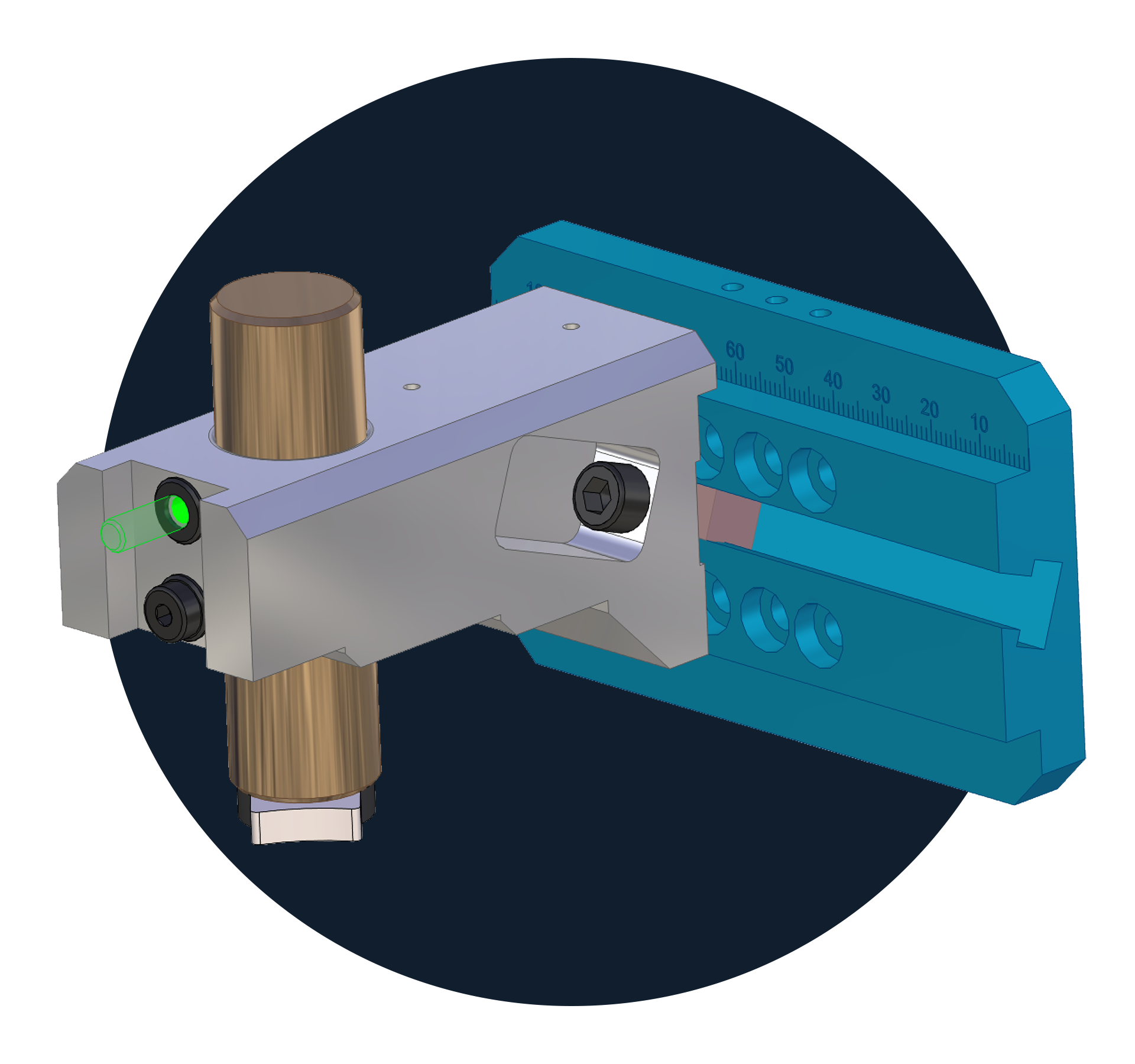

Reinventing the wheel

Robotics company Wheel.Me hopes to transform how goods and equipment are moved across factory floors. Get a close-up look at their latest product, the Genius 2, and why they switched from SOLIDWORKS® and Autodesk Fusion 360® to Solid Edge from Siemens to keep its iterative electromechanical design process rolling forward.

Why switch to Solid Edge?

While switching 3D CAD software platforms may seem like a massive undertaking, continuing to rely on an existing platform for sake of convenience can cost you valuable time, money and resources. If you recently considered switching platforms or are not completely satisfied with your current workflow, here are some of the top reasons to switch to Solid Edge…

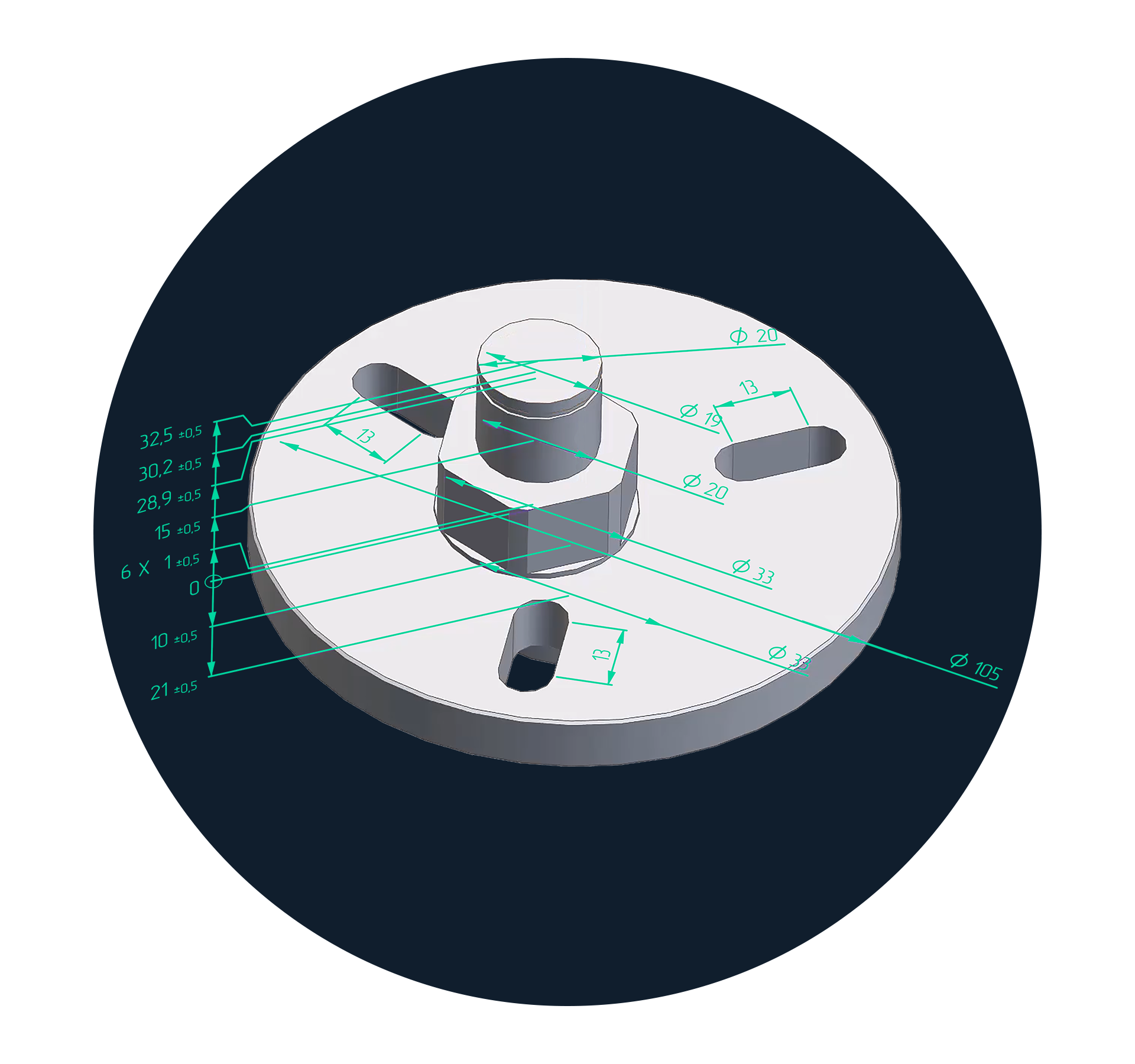

Improved design documentation

Easily exchange information between engineers, suppliers and manufacturers with a robust set of 2D and 3D drawing tools. Designers can create drawings directly using 2D workflows derived from 3D models or with a hybrid approach. With model-based definition (MBD) capabilities, the 3D models include PMI and other digital data using universal 3D PDFs. Users can access and view interactive representations of the manufacturing data.

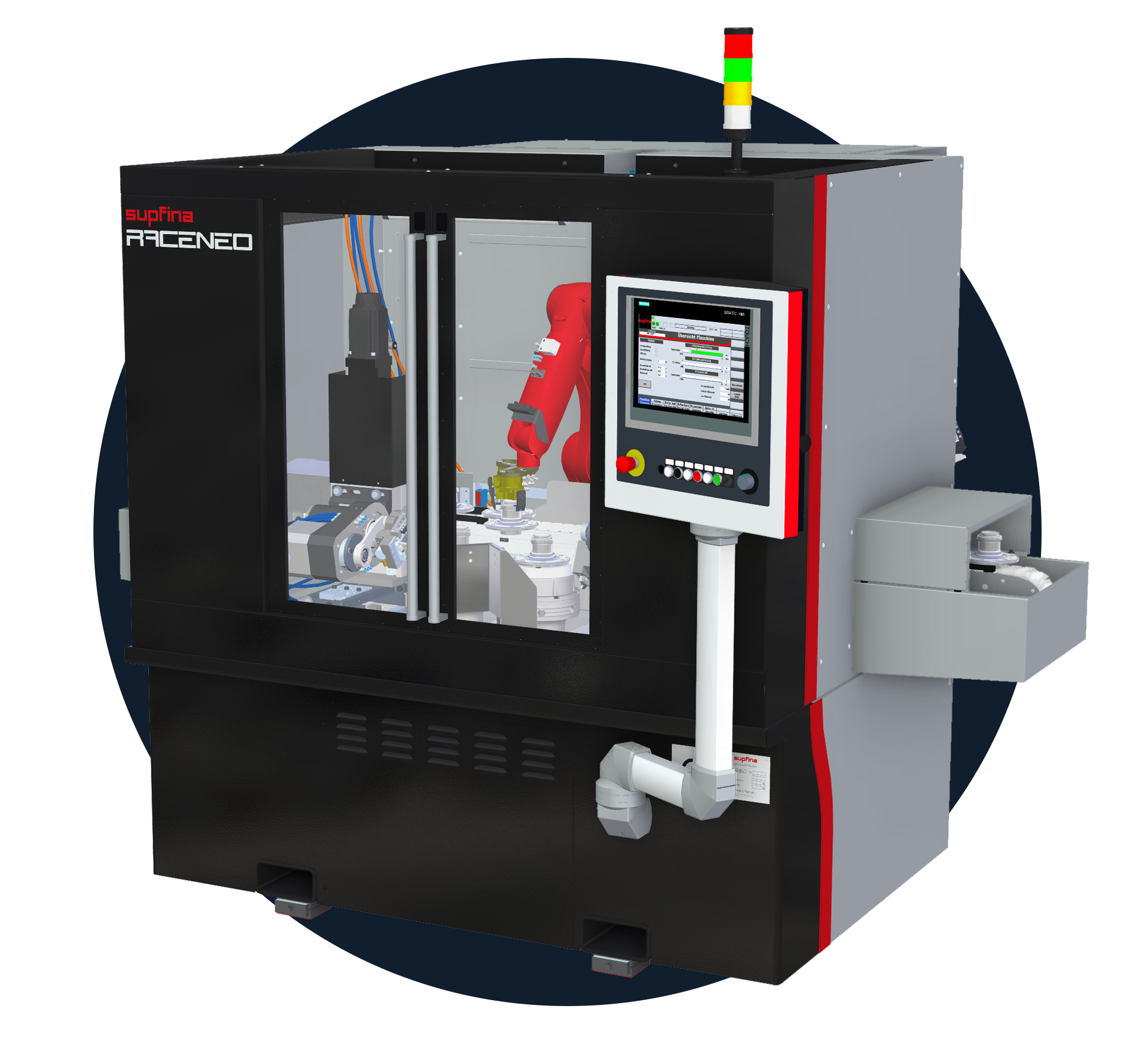

Faster assembly performance

Don’t waste time re-creating or duplicating lost work or waiting for your assembly to load. Solid Edge allows designers to seamlessly work across large assemblies in real-time with an uncompromised, immersive digital experience. Thanks to its high performance and seamless usability, designers realize productivity gains with Solid Edge as they work with their designs. View and manipulate the largest assemblies without lags, stutters, or buffering. Immersive View Styles place your 3D assembly models in a real-world environment that automatically updates with model movement for improved realism.

Better sheet metal design

Don’t compromise when it comes to sheet metal – Solid Edge provides sheet metal specific design features to allow you to easily add drawing details and automate calculations of material relief. Develop models from 2D sketches with fewer steps and make changes at every stage of the sheet metal design process, while maintaining design intent.

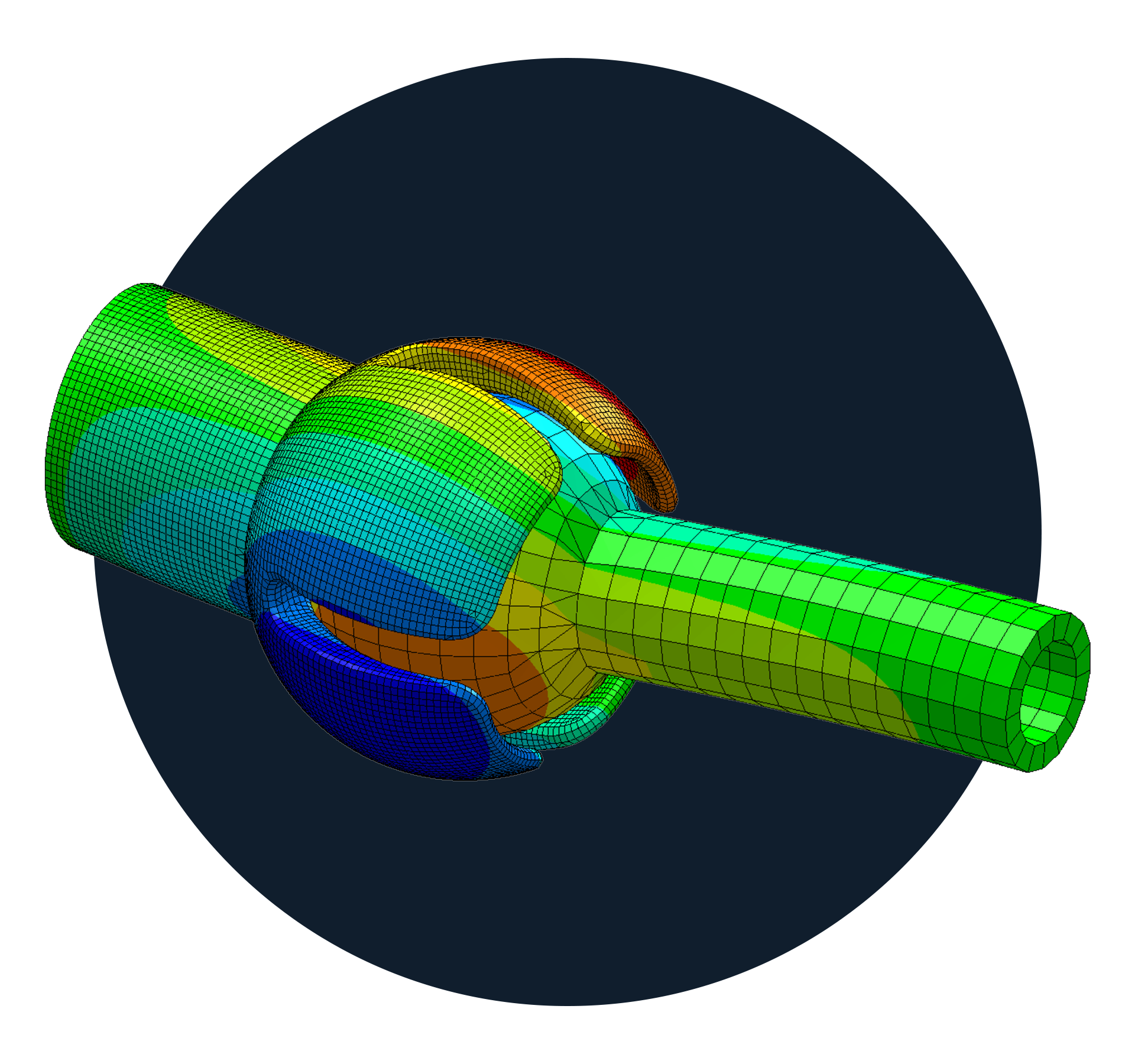

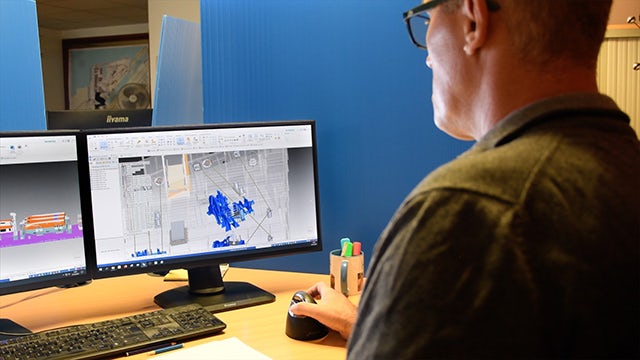

Less time re-modeling and creating

Don’t re-create 3D models to match data from scanners, printers, or finite element models. In conjunction with powerful 3D design tools powered by synchronous technology, Solid Edge delivers smart functionality to work with mesh or triangle-based data. Revise mesh density, fix and repair problems with faceted geometry, and use feature-like operations to add holes, rounds, cuts, protrusions. Rapidly create new concept designs, easily respond to change requests, and make simultaneous updates to multiple parts within an assembly. Treat multi-CAD data just like native files, supporting seamless collaboration with suppliers and partners.

Accessible industrial design

Bring easy-to-use, integrated industrial design tools to your mechanical engineers and incorporate aesthetic design into your product development process. Using subdivision modeling, Solid Edge provides advanced yet accessible industrial design capabilities. Designers can create complex and highly controlled aesthetic surfaces using Solid Edge’s intuitive subdivision modeling toolset. It is suitable for users with any CAD expertise level, allowing them to create highly stylized shapes with ease.

AI-powered software that understands you

Solid Edge intelligently learns your workflows to help you streamline the design process with a predictive user interface, powered by Artificial Intelligence (AI) and machine learning. Solid Edge predicts what operations you are likely to want to perform based on previous user behavior, improving your downstream productivity.

Interoperability for data across CAD systems

In a recent survey, more than 50% of CAD users cite working with imported data as a “top 5” challenge. Regardless of where your design data originates, Solid Edge makes working with it easy. In addition to the ability to leverage design data created in other CAD applications in Solid Edge, recent enhancements to CAD Direct, Data Translation and Migration capabilities make it even easier with an expanded roster of supported formats. Whether you’re switching from another CAD system, reusing legacy design data, our working with suppliers, Solid Edge makes working with third-party files as easy as native data.

File sharing and collaboration from any device

Instantly, securely, and easily collaborate with colleagues, partners, and customers with Siemens’ next-generation cloud collaboration solution, Teamcenter Share – available through your Solid Edge XaaS subscription, as well as with online purchases of eligible Solid Edge portfolio products. Streamlined integration, powerful productivity features, and extended storage and file support help you improve communication and move projects forward from anywhere, on any device.

Flexible licensing options

A modular, scalable CAD application, Solid Edge is available through monthly or annual Siemens Xcelerator-as-a-Service (XaaS) subscriptions that connect you to the cloud and provide the opportunity to subscribe to software and services based on your needs. With Solid Edge XaaS, you can lower IT overhead, manage costs, and easily scale your business, plus access extra features only available through a XaaS subscription.

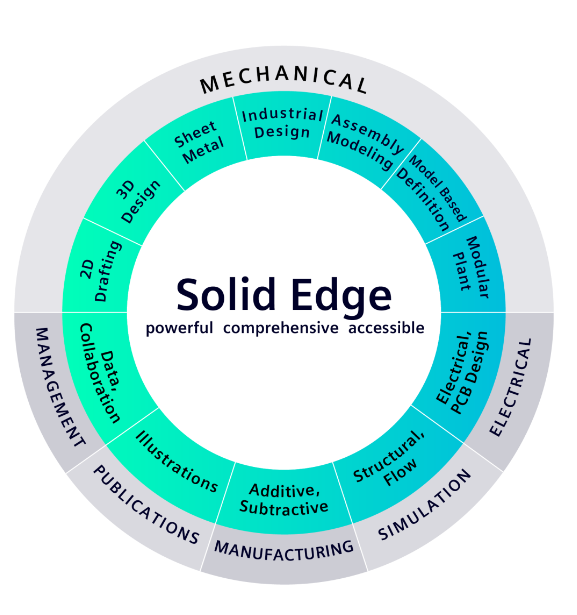

A complete product development software portfolio

Solid Edge is a portfolio of affordable, easy-to-use software tools for all aspects of product development – mechanical and electrical design, simulation, manufacturing, technical publications, data management, and more.

Solid Edge has something for everyone, especially SOLIDWORKS users looking for an alternative.

Matt Lombard, Author of the SolidWorks Bible & Blogger @ Dezignstuff

Solid Edge makes it easy to switch

Data migration tools to seamlessly import and manage your data.

Experienced local support partners who are ready to help.

Access to a complete portfolio of software tools for every aspect of product development.

Solid Edge is a multi-faceted software portfolio and includes a wide range of applications and features that make it the preferred choice for professionals across industries and companies of all sizes.

However, this can make it complex for first-time users, regardless of their prior CAD knowledge.

We offer a variety of self-guided tutorials to help you get up to speed with Solid Edge, including the Solid Edge GUI (Graphical User Interface) and basics of 2D/3D modeling, and more. New users can learn the basics in a little as 1 hour!

For users making the switch from SOLIDWORKS, the Command Finder in Solid Edge allows users to enter a familiar SOLIDWORKS command and it will return the equivalent command in Solid Edge.

Most CAD companies use the “File Open” method for working with non-CAD data. Solid Edge can open up data from a lot of different systems, including SOLIDWORKS, STRC, ProE, Inventor, CATIA, and AutoCAD. There are drawbacks to this method, however, which is why we recommend using the SOLIDWORKS Data Migration Tool.

Benefits of using the SOLIDWORKS Data Migration Tool include:

- Drawing Migration: If you look at the drawing of an assembly, you can see all the views, balloons and bill of materials migrated into Solid Edge.

- Subassemblies & Assembled Relationships: The “Assembly Relationship Manager” is a summary of all the assembly relationships within a particular assembly. Within the Manager, you can modify each one of the relationships—all of which came straight from the SOLIDWORKS files. If you select parts from the “Pathfinder,” you’ll notice that all of the parts have relationships within the assembly.

- Rearrange Drawing Views: You can drag any view around within a drawing, and all the views will stay aligned, as they should.

- Hole Features: With the SOLIDWORKS Data Migration Tool, all hole features will migrate specifically as holes. This means that any hole can then be selected and changed in Solid Edge.

- Material & Property Migration: Materials and custom properties also migrate from SOLIDWORKS to Solid Edge. Because of this, there’s no reason to change any sketches if you want to make an edit—you can simply drag faces of parts or enter a value.

- Fully Associated Files: Because part and drawing files are fully associated, any drawing files will update whenever you make edits to the corresponding part file. There’s no need to go back and double up on work.

The short answer: YES; many companies are making the switch to Solid Edge. Here are a few real-world examples:

- Chantiers de ‘Atlantique: this industry-leading shipmaker uses Solid Edge to refine complex and detailed design concepts. They previously had multiple computer-aided design (CAD) packages and enterprise resource planning (ERP) software solutions to harness the overall complexity of designing and constructing an immensely large cruise ship, such as the Wonder of the Seas. To optimize the creation of the cabins, they switched from SOLIDWORKS® to integrated Solid Edge software, which is used by their in-house design teams, engineers and marine experts.

- DesignPlan: This multi-national urban lighting business switched to Solid Edge after 25 years of experience with other CAD solutions. With the help of Solid Edge synchronous technology, they’re able to design customized products with speed and efficiency, without sacrificing product quality.

- B&P Littleford: The biggest challenge for B&P Littleford was delivering designs on time. It has projects for different types of machinery so design drawings have to be released in a clean, concise manner without having to make excessive engineering change orders (ECOs). They need to avoid correcting designs because they went too fast and made mistakes while being innovative. That’s always the challenge: speeding up the process and becoming more efficient while still maintaining some creativity and innovation. The company switched to Solid Edge from SOLIDWORKS and hasn’t looked back.

According to Matt Lombard, a well-known CAD blogger and online influencer, Solid Edge has something for everyone, especially SOLIDWORKS users looking for an alternative. Read the full article here.

Siemens operates solely on the Parasolid kernel for all of our CAD products, including Solid Edge—a first in industry from a single provider. This enables us to provide varied capabilities, at different price points, in a cost-effective, scalable package. Both Solid Edge SOLIDWORKS operate on the Parasolid kernel which is essentially the operating system for any 3D CAD software platform. Whenever you draw a line or make a calculation, it is Parasolid that does the heavy lifting for you.

And because Siemens owns, develops and openly shares Parasolid, we’re able to provide unmatched protection for your company’s data and technology investments, while ensuring easy data migration from other CAD products that operate on Parasolid.

Learn more: The Hidden Cost of Swapping CAD Kernels by Schnitger Corporation

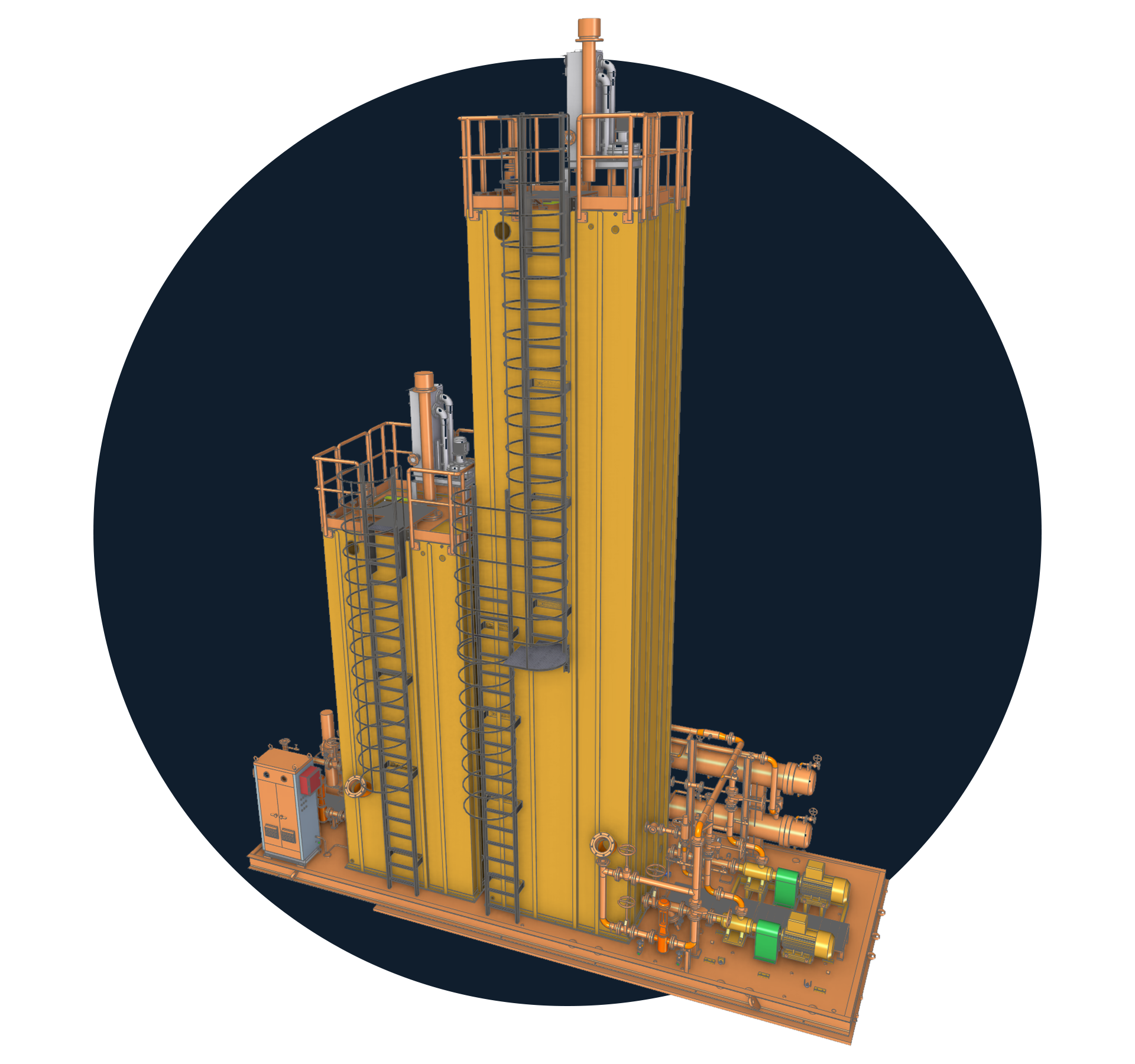

Solid Edge delivers unmatched performance for large, complex assemblies. While you may have become accustomed to frequent crashes and 20+ minute load times to open an assembly using your current CAD system, Solid Edge handles assembly operations faster than other professional CAD solutions on the market today.

As designs become more complex, the number of parts in an assembly often grows. Solid Edge helps you quickly and easily create and manage even the largest assemblies, without lags or crashes. Create exact representations of all components—including tubes, pipes, wires, weldments, and sheet metal—in a complete digital mockup that allows for more accurate design and analysis. Solid Edge helps you quickly detect and fix clash and interference issues, generate assembly instructions, and conduct customer reviews—reducing the need for costly prototypes.

Dive Deeper: 5 Tips for Large Assembly Performance (white paper)

Solid Edge provides users with a complete portfolio of affordable, easy-to-use software tools that addresses all aspects of the product development process–3D design, simulation, manufacturing, data management, and more. Solid Edge combines the speed and simplicity of direct modeling with the flexibility and control of parametric design – made possible with synchronous technology.

Software adoption is a key ingredient for success in any organization. When employing new CAD users, you want the best for your business. A common driver for customers switching from other CAD software is the difference compared to Solid Edge. Solid Edge is used by thousands of colleges and universities, and businesses worldwide who have existing experience with Solid Edge products.

With Siemens Xcelerator Academy, new users can master Solid Edge and other key elements of the Siemens Xcelerator portfolio to become leading experts in Siemens software. Training and learning opportunities include live training, online certification programs, guided learning programs, and dynamic learning maps.

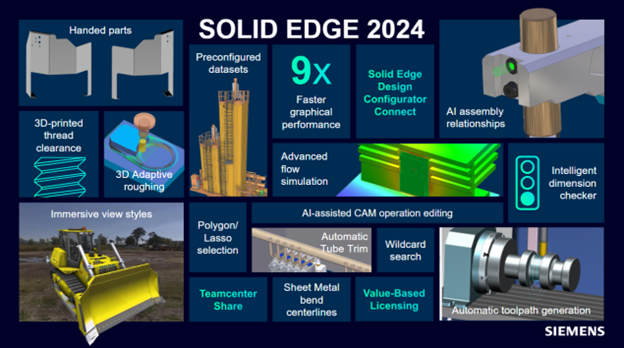

Solid Edge is updated every year as part of an annual update, with a focus on delivering new features and enhancements that our customers value most. But unlike many other CAD tools, Solid Edge ensures that your legacy data is protected.

An integral part of the comprehensive Siemens Xcelerator portfolio of software and services, Solid Edge is a great entry point for small- and medium-sized manufacturers with flexible options to access different Siemens products as your business grows.

More information about what’s new in the latest version of Solid Edge is available here.

Solid Edge has been certified to run on a variety of operating systems. A detailed list of system requirements is available here.

Ready to make the switch? Get in touch with us today to request a demo and discuss your options!